Among the most widely used resins in a whole range of industries is epoxy. At the forefront of many manufacturing processes is also the ever evolving technology called epoxy potting. From surface mount adhesive application on PCB assemblies to filling heavy-duty terminals for potting, epoxies work by protecting sensitive electronic components from dust and heat.

Popular Types of Epoxy Potting Machines

XYZ Dispensing robots are easy to set up and can be used in minutes. Epoxies are tougher than most other potting and adhesive substances, especially against chemicals and changes in temperature. Some types of epoxies can even survive extreme temperatures, making them the best choice for potting and encapsulation. Several types of epoxy machines allow for faster and more efficient application of the resin. For minor projects, applying the resin manually with the help of a toothbrush is also possible.

A very simple type of epoxy potting machine is called a manual handheld dispenser which is shaped like a gun. When the trigger is pulled, the dispenser releases the epoxy contained in tubes that are fitted into the machine. There are many kinds of automatic epoxy potting machines such as the pneumatic dispenser. There are also systems which come with a head that can be focused over a work table in different angles. These dispensers are highly precise when depositing epoxy, making them a common tool used in industrial environments.

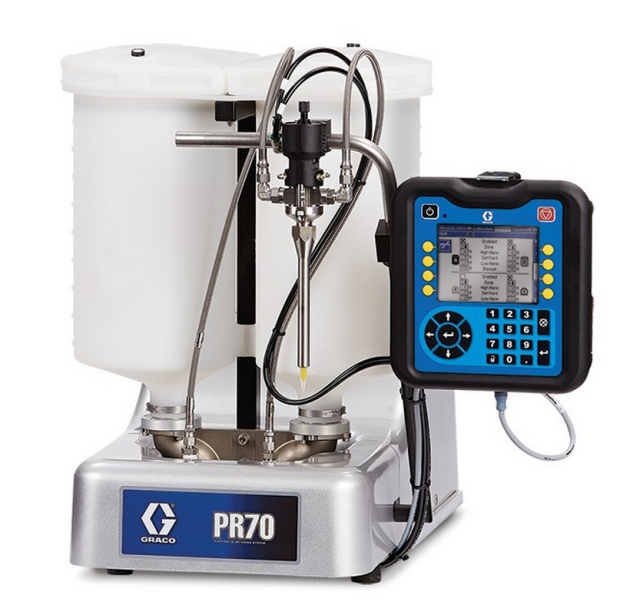

Electronic Potting Machines

When heated, epoxide and polyamine combine to form epoxy adhesives. During the dispensing process, the hardener and polyurethane resin are thoroughly mixed. Related articles pertaining to this are provided in the site at http://www.britannica.com/EBchecked/topic/1372259/epoxy. In major manufacturing processes, computer-run and precision-controlled electronic dispensing machines control epoxy potting. This means minimum adjustments may be made to the location and quantity of the resin in order to produce high quality output. These machines also eliminate or reduce the possibility of human error which may otherwise prove to be costly during the dispensing process.

Epoxy Potting Pointers

To ensure that there will be no epoxy blockage on the dispensing unit's tip, it is important to clean the dispenser and potting equipment before storage. Clogs may be removed through the cutting of a hardened polyurethane resin while using a blade or sharp blade. There are epoxy potting machines which have a tip cover, allowing you to seal the tubes when they are not in use. In any case, be sure not to overdispense epoxy adhesives, and that all excesses are instantly wiped off before the curing.

Epoxy-curing Oven

For speeding up the curing process, an epoxy curing oven does a perfect job. Read more about it at http://dispenserite.ca/meter_mix_dispense_machine.html. The epoxy has to be left to cure, then heated. Three important issues to look into before buying an oven are heating capacity, overall size and available internal space. One disadvantage of curing ovens is their cost, but this is well-compensated by the fact that no additional shifts or production lines are needed to cope with demand.